Alles im Lack

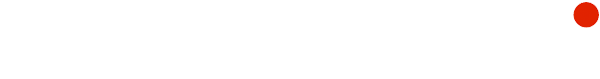

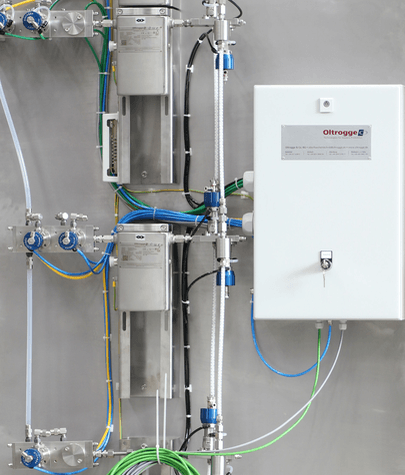

Wer schon einmal den Versuch unternommen hat, eigenhändig die Stoßstange seines Autos zu lackieren, der erahnt die Bedeutung automatischer Misch- und Dosieranlagen für die industrielle Serienfertigung. Die vier Anlagenvarianten der Baureihe “Regular” verarbeiten anspruchsvolle 2K- oder 3K-Lackmaterialien. Durch die mengengeregelte Dosierung aller Komponenten wird ein perfektes Mischungsverhältnis und damit eine erstklassige Oberflächenqualität erreicht – einfach, umwelt- und bedienerfreundlich.

Ob Lösemittel- oder Wasserlack, niedrig- oder hochviskos, konventionell oder elektrostatisch, Niederdruck- oder Hochdruckapplikation, Automatik- oder Handbeschichtung: Die Bielefelder Anlagen – allesamt ausgelegt auf schnelle Farbwechsel und leichte Spülbarkeit – bieten die passende Technik für unterschiedlichste Anwendungen. Durch den Verzicht auf ein zusätzliches Härterventil, auf Druckregler oder Vormischkammer reduzieren sich die Ausfallzeiten, die Wartungs- und Ersatzteilkosten. Weitere Pluspunkte sind die bedienerfreundliche Touch-Screen-Steuerung sowie die Standzeitüberwachung der Dosierventile. Das Datenerfassungs- und Prozessanalyse-Portal “Zelox Smart” unterstützt optional die Transparenz und Fehlerminimierung.

Oltrogge liefert innovative Oberflächentechnik als Fullservice. Jeder Dosierfall wird individuell konstruiert und programmiert. Mit Produkten und Services von Oltrogge arbeiten Sie als Kunde prozesssicher und bei hoher Verfügbarkeit und Ressourcenreduktion. Eine Kombination für höchste Effizienz und Wirtschaftlichkeit.

Der technische Lösungsanbieter und wertschöpfende Lösungsanbieter hat seinen Hauptsitz in Bielefeld. Die Leistungsschwerpunkte des in fünfter Generation geführten Familienunternehmens liegen in den Produktbereichen Oberflächen-, Druckluft- und Schweißtechnik sowie im Bereich Werkzeugmaschinen. Oltrogge beschäftigt rund 150 hochqualifizierte Mitarbeiter an fünf Standorten und ist strategischer Partner für rund 15.000 zufriedene Kunden.

Weitere Informationen zum Partner